If you have worked with the WMS module introduced in AX 2012 R3, you may have struggled with understanding the on-hand form in AX. Especially the reservations in the on-hand form tends to create some confusion among AX users… and consultants 🙂

Some of this confusion comes from the fact that AX supports reservations at both warehouse level and at location/license plate level and these reservations serve different purposes and have different consequences.

In this post I will walk through the basic order and warehouse transactions and discuss the effect on the on-hand form with focus on reservations. If you have never worked with the on-hand form before, you can find a basic introduction to the fields here: https://technet.microsoft.com/en-us/library/aa616522.aspx

Important note: The example in this post is based on a batch controlled item with batch dimensions setup below location in the reservation hierarchy. Items setup with batch above location will behave differently in regards to on-hand and reservations. Going into details about that will require a separate blog post…

A simple example…

To illustrate how the various transactions affects on-hand and reservations I will use a simple example with one sales order and one purchase order and follow the items through the warehouse.

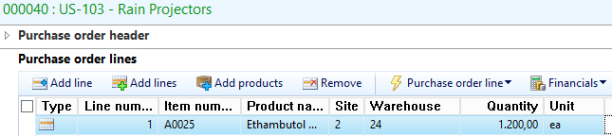

I have created a purchase order …

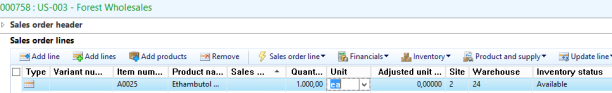

… and a sales order

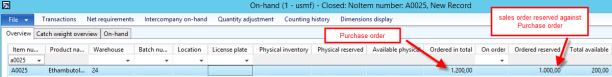

The sales order has been reserved against the items ordered on the purchase order. In the on-hand form it looks like this:

The purchase order can be seen in the Ordered in total field, and the 1000 reserved from the sales order in the Ordered reserved column.

If you have worked with earlier versions of AX there should be no surprises so far.

On-hand after Item receive

Now the item is received on 3 pallets with license plates LP01, LP02 and LP03. All 3 pallets with batch B01.

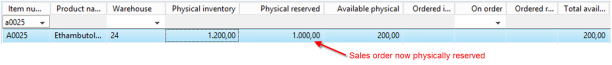

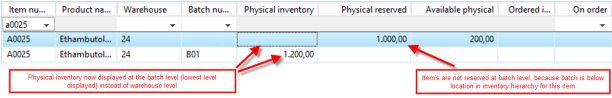

If you open the on-hand form now and only display on warehouse level it’s easy to see the effect of the item receipt. 1200 is now registered as physical inventory, with 1000 being physical reserved to the sales order, leaving 200 available physical for other sales orders:

If you activate the batch dimension in the on-hand form, the result looks slightly different:

Note that the Physical inventory is now displayed at the batch level, instead of the warehouse level. This is because AX will display the physical inventory at the lowest possible storage dimension selected in the form. In this case it’s the batch level.

Another important thing to learn from the picture above is that the sales order reservation of the 1000 is only displayed at the item/warehouse level and not at the batch level. This is because sales order reservations are only performed at the item/warehouse/inventory status level. Sales orders are not causing reservations at more detailed storage levels like batch (unless batch is setup for batch above location in reservation hierarchy), location and license plates. And that is actually a nice thing for warehouse operations – not having sales to dictate which location, license plate etc. should fulfill a particular sales order.

Lesson: Sales order reservations only reserves at item/warehouse/inventory status level and not at detailed storage levels like location, batch or license plate.

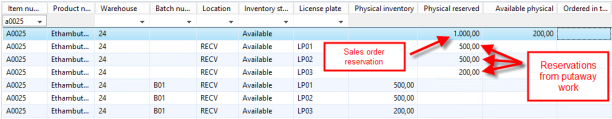

If you activate location and license plate storage dimensions, the on-hand form looks like this:

First thing to notice is the Physical inventory is now displayed at the license plate (pallet) level.

The next thing to notice is the Physical reserved field. The sales order still has a reservation of 1000 at the item/warehouse/inventory status level. But there’s now 500+500+200 reserved on license plate LP01, LP02 and LP03. These reservations are caused by putaway work created when we received the items. The putaway work states that the pallets must be moved from the RECV location to a location in the warehouse.

The license plate reservations are different by nature than the sales order reservation and have different consequences. The license plate reservations have no effect on the physical available quantity on the item/warehouse/inventory status level. So it’s still possible to reserve the remaining 200 physical available to another sales order, even though 1200 seems to be reserved at license plate level.

Lesson: Putaway reservations from pending putaway work will not affect/block sales order reservation

It is however not possible to release a sales order while items are still reserved to putaway work. So you will need to put the items in the warehouse before sales orders can be released to warehouse and pick work can be created.

Lesson: Putaway reservations from pending putaway work will block for release of sales order to warehouse.

One final note is regarding the Physical reserved column. As opposed to the Physical inventory you can never calculate a the total physical reserved for an item by summing the values in the Physical reserved column. This is not possible because reservations at different storage dimensions are not comparable.

Lesson: Never summarize reservations across different storage dimensions.

On-hand after putaway

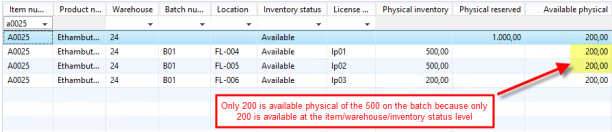

Now the items are putaway to locations in the warehouse. If you open the on-hand form with warehouse, location, batch number and license plate displayed, the form looks like this:

From the form you can see that the three pallets have now been placed at location FL-004, FL-005 and FL-006. You’ll also notice that all putaway reservations have been removed. Only the sales order reservation of the 1000 remains.

At this stage the warehouse can move the pallets around in the warehouse, because a reservation only exist at the item/warehouse level.

Lesson: Sales order reservations do not prevent movement of items within the warehouse

Note that the Available physical on the license plate LP01 and LP02 is only 200. This is because the total available on the item/warehouse/inventory status level is 200. This overrules the 500 on the license plate. If you try to change the inventory status on the pallet LP01 from available to blocked you will get error because only 200 is available physical and the license plate qty is 500. But if you try the same with pallet lp03 you will be able to change the inventory status because the complete license plate quantity (200) is available physical.

A final important thing to observe is that you can’t calculate the total physical available by just summarizing the Available physical column. If you do that in the above example you’ll get the faulty impression that 800 is physically available, where the correct answer is 200.

Lesson: Never summarize the Available physical column

On-hand after release to warehouse

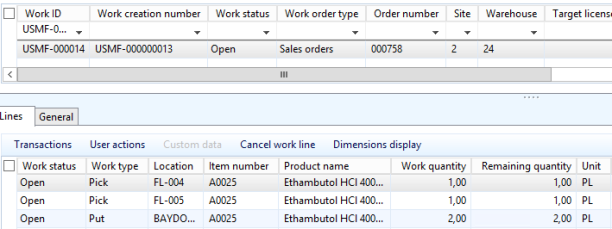

The sales order is now released to warehouse and work is created:

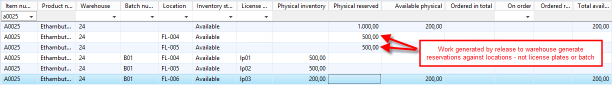

The effect on the on-hand form:

Two new reservations from the pick work is generated against locations FL-004 and FL005. Note that the reservations are not generated against batches or license plates. The warehouse worker is free to pick any license plate/batch found at the location.

Lesson: Pick work generates reservations against pick locations, not license plates

The pick work reservations on the locations has the effect/consequence that it’s not possible move the items on these locations around anymore. This is a known limitation in the new warehouse module – that can be a hassle especially for staged items – but that’s another post.

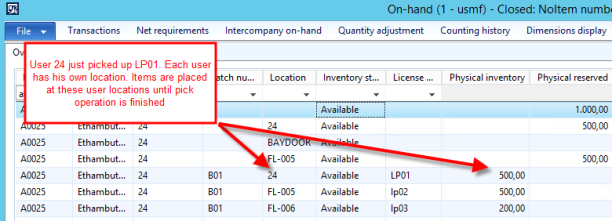

On-hand during pick of items

Now the warehouse worker 24 arrives at the first location and picks up the first pallet. If you open the on-hand form now you’ll see that that pallet LP01 has been moved to location 24. The pallet will remain here until pick work has been completed. Location 24 is special warehouse worker location. All warehouse workers will have location named after their worker name. These locations are used to hold items picked to work but not yet put

Lesson: During pick (and other) work items will be placed at a user location.

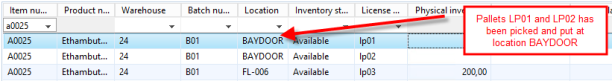

On-hand after pick

When all pick work has been completed the on-hand only contains the remaining quantity of 200. The 2 empty lines for license plate LP01 and LP02 will disappear when the packing slip is posted.

Recent Comments